CASE STUDIES (SUCCESS STORIES)

CEMENT PLANTS

Kiln Feed Bin Level Fluctuation Optimisation.

- ISSUE :: Bin Level Fluctuating with repeated cycle 81.2 to 86.5 Tons

- ACTION :: Gate Opening for 1 & 2 readjusted. Other Gate Operation Optimized.

- Diagnosis:: Fluctuations coming due to malfunctioning of the discharge gates (Mechanical issue,No where related to Controller tuning / PID).

- RESULT :: 70% reduction in fluctuations. Bin level maintained between 85 to 86 Tons.

- BENEFIT :: Reduces effect on Kiln Feed Rate fluctuation.

Kiln Feed Flow Meter Fluctuation

- ISSUE :: Sudden Peaks in Kiln Feed.

- Diagnosis:: Abnormal (non-linearity) Sensor response at higher feed flow rates.

- Sensor Anomaly detected as source of Major fluctuations

- Action:: PV Filter for kiln feed PID.

- RESULT :: The Instrument Related spikes were detected & eliminated which reduced the side effect of False Alarm.

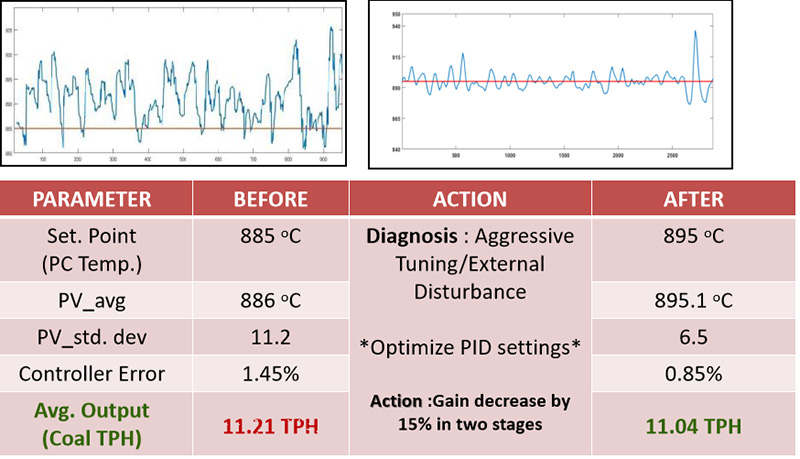

PC Temperature Fluctuation Assessment Optimisation of Fluctuations in PC temperature (Master Loop Optimisation)

- ISSUE :: Manual mode operation & Suboptimal PID Settings.

- ACTION :: Manual mode Operation was shifted to AUTO mode Operation and the response were corrected by Optimizing PID settings.

- RESULT :: Stable Pre-Calciner Temperature.

- BENEFIT:: Small amount of coal TPH reduction can lead to big savings..3.6 TPD coal being saved ~ nearly 22000 Rs/day saving.

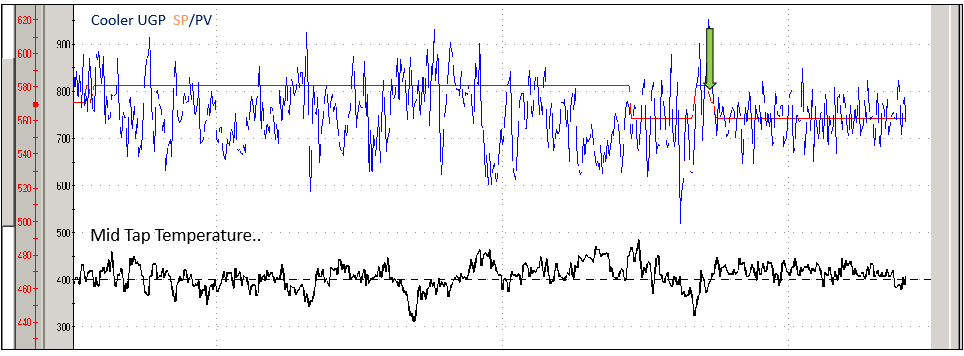

Cooler Under Grate Pressure AUTO operation.

- ISSUE :: Cooler Chamber Pressure vs. Cooler Grate Speed PID was running in Manual mode as it is not stable in AUTO mode.

- Diagnosis:: Operation in Manual.

- ACTION :: Operated in AUTO mode + Fine Tuning of Controller parameters.

- RESULT :: Actual Under grate pressure is fluctuating around the required set point (+/-20 mmWC). Stable and consistently above 400 oC Mid Tap Temperature.. >> stable WHR operation.

- BENEFIT:: Cooler operation optimized to achieve higher outlet gas temperature (stable above 400 deg C). Which helps them to achieve higher power generation in WHR (waste heat recovery) plant.

Assessment of Diffuser Amps for Drum Level Control.

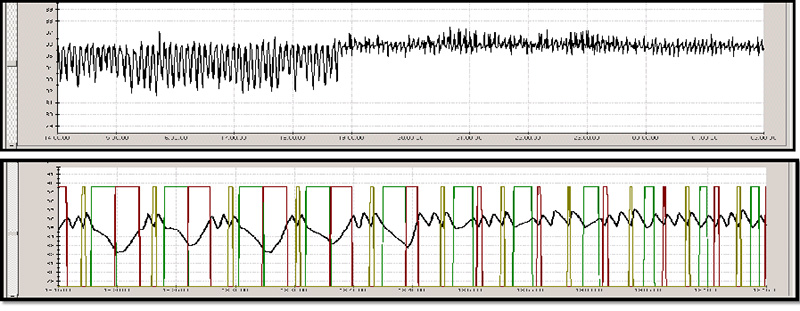

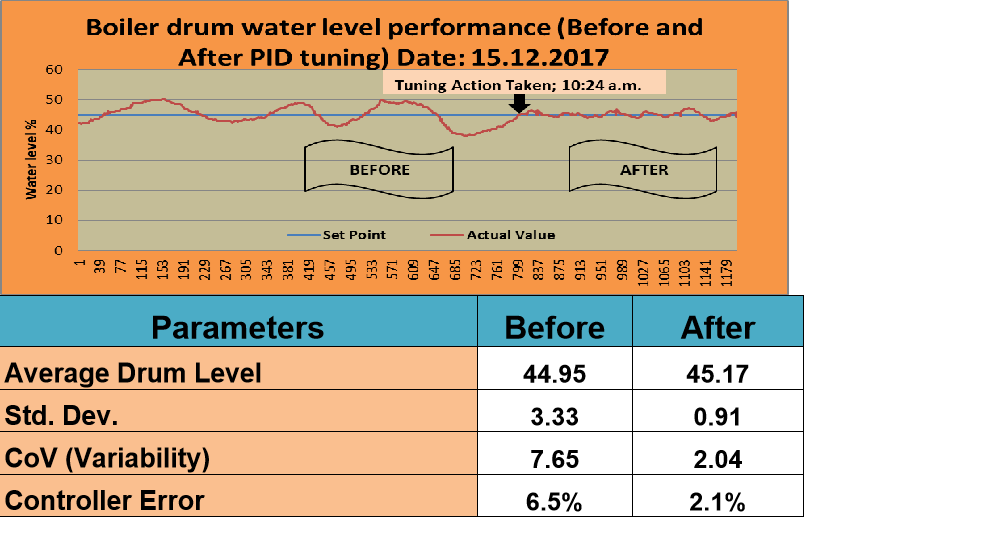

* CAPTIVE POWER PLANT * Drum Level Control

- ISSUE :: Variability in Boiler Drum Level. Optimisation of variability in Boiler Drum level.

- Diagnosis:: Sub-Optimal PID Settings. Action: PID Tuning.

- ACTION :: Operated in AUTO mode + Fine Tuning of Controller parameters.

- RESULT :: Lower deviation in drum level.

- BENEFIT:: lower thermal shocks + lower variation in boiler pressure.

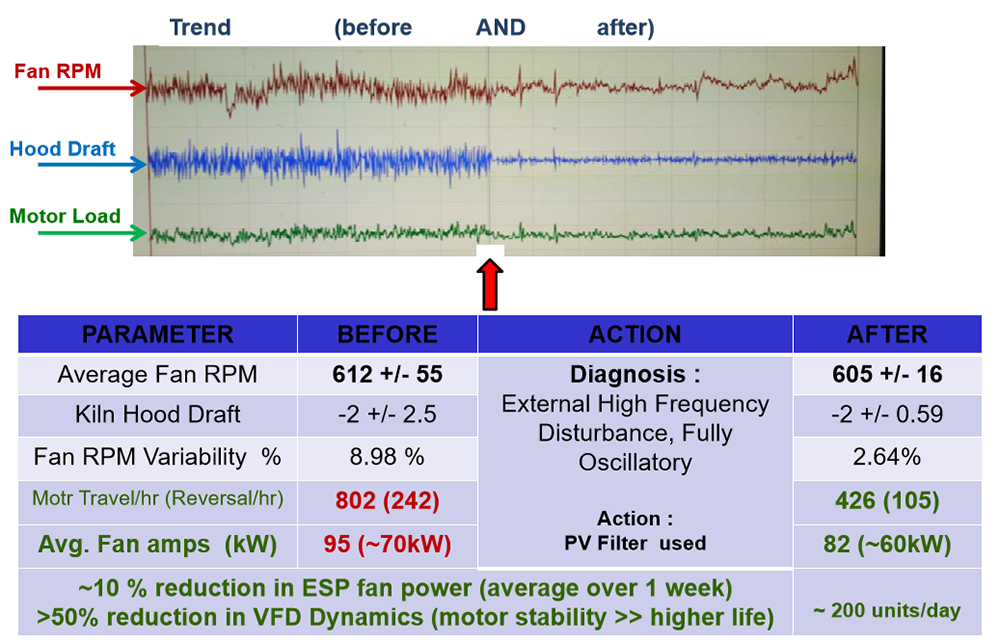

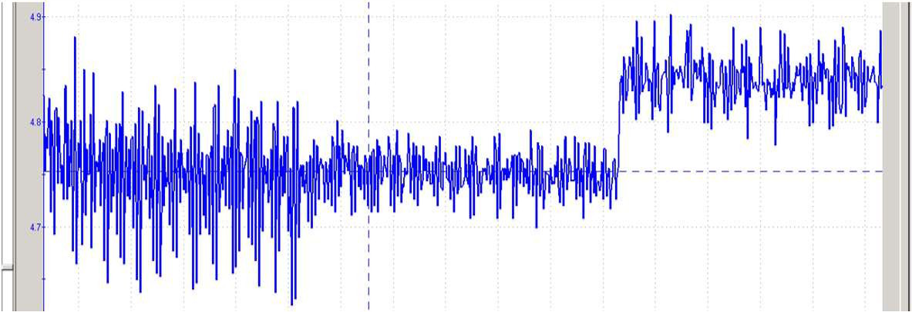

Assessment of ID fan related fluctuation

Boiler House Draft Control (ID Fan) Stabilisation

GRINDING

Gypsum Feeder (in Cement Mill) Fluctuation Optimisation

- ISSUE :: Gypsum Weigh Feeder showing higher variability (>5%) even for fixed set point.

- Diagnosis:: Weight Feeder speed response issue (Panel Settings to be optimized).

- ACTION :: Parameters adjusted in Schenck Panel (Gain factor increased from 0.2 to 0.6 mA%).

- RESULT :: More than 70% reduction in variability. No its operating with SP +/- .05 TPH (<1% variability) as compared to SP +/- 0.2 TPH (>5% variability across Set Point)).

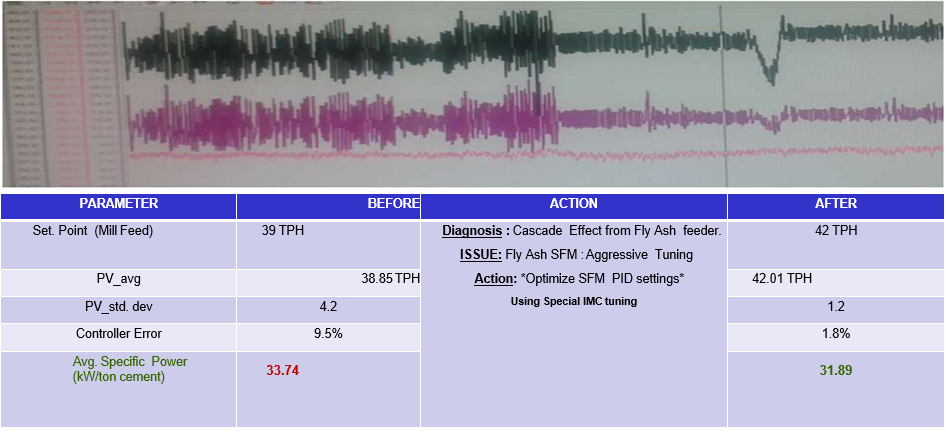

Optimization of Fly Ash Feeding (SFM) Fluctuations (critical to open circuit).

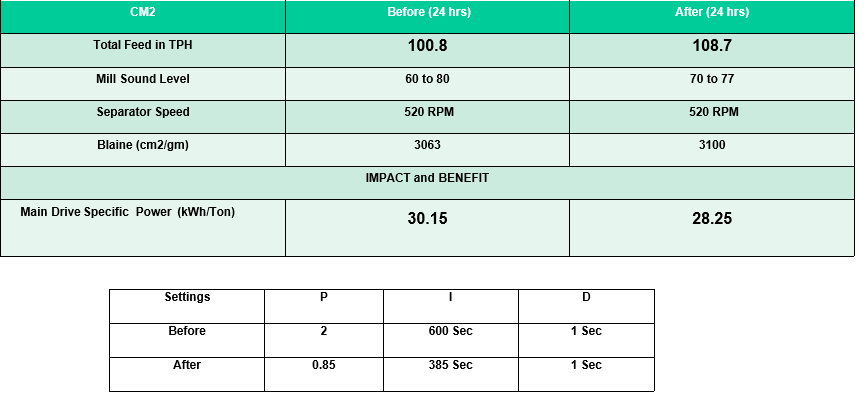

TWO Chamber Ball Mill (Closed Circuit) – OPC Grinding Sound level vs Feed PID optimisation

Progressive Assessment/ Optimisation of Raw Mill (Roller Press + Ball Mill) Operation.

POWER PLANT

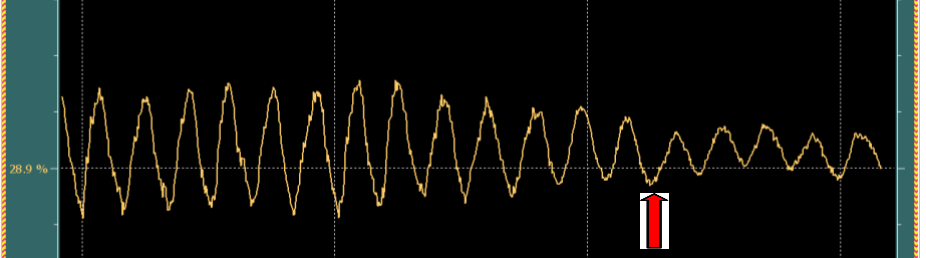

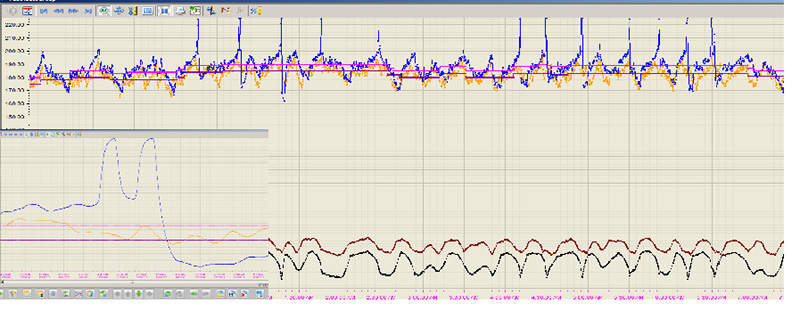

Drum Level Control

- OBSERVATION :: Low controller performance,5.8% error.

- DIAGNOSIS:: Oscillations due to Agressive tuning.

- ACTION :: Parameters adjusted in Schenck Panel (Gain factor increased from 0.2 to 0.6 mA%).

- CORRECTION :: ‘I’ action reduced by 20%.

- RESULT :: Zero Oscillations, Average error < 1%.

- EFFECT :: Stable Steam Pressure / Quality (better Steam Economy)

PULP & PAPER PLANT

Assessment/Diagnosis of Fluctuations in Reagent Quality

BENEFITS / SAVINGS

REDUCED VARIABILITY IN OPERATION

MINERAL PROCESSING PLANT

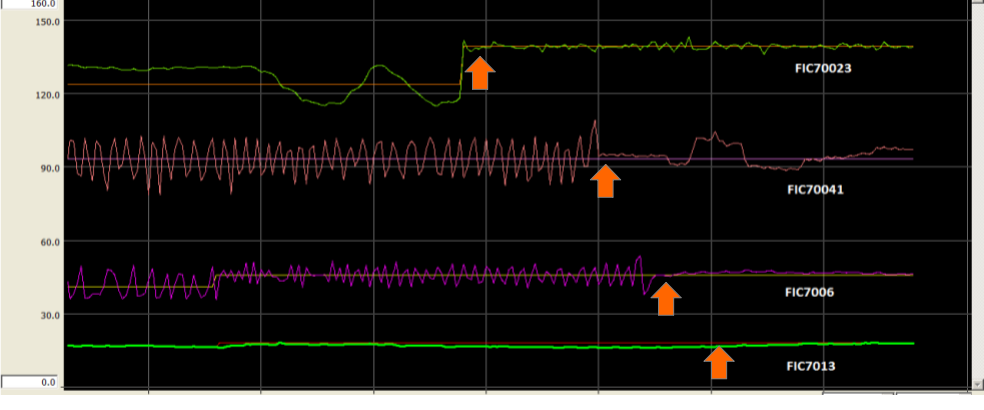

Assessment/Diagnosis of Fluctuations in Mill Section (Flow and Level Variation)

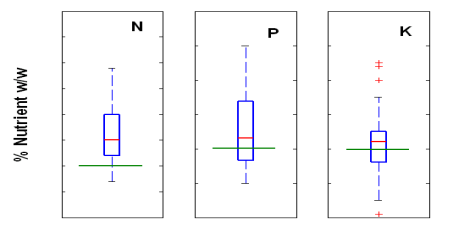

FERTILIZER PLANT

Assessment/Diagnosis of Fluctuations in Nutrient Quality

- Variance Diagnosis :: Spot Sampling Effect, Unmeasured Disturbance, Oscillating Inputs,Slow Controller Response, Valve Related Issues.

- Actions suggested :: AUTOsampler (composite sampling), PID tuning, New Measurements for external disturbances, Valve servicing.

-

Result ::

PARAMETER BEFORE AFTER BENEFIT Upper Limit Deviations 30-35% 14-15% 2% lower input material cost Lower Limit Deviations 7-8% 3-4% 15% reduction in OffSpec rejection

PHARMACETICALS

Tablet Coating Machine Control Optimization.

-

Parameter Before Change After Changes Remarks Hot Air Inlet Set Point 70°C 70°C Starting point Absolute Controller Error % 49 mm 8.5 min (SP-PV)/ SP Average over time % Overshoot above set point before stabilizing back 2.1% 5.6% Overshoot reduce to SP within 5min. Standard deviation in Temperature during stable control (after SP Reached) 0.26 0.16 Average deviation temperature set set point over 3 hour operation cycle. Average Value Opening 71.3% 53.4% Average over start up time Steam consumed during Start-up (kg) (assuming 'S' kg/min steam rate at 100% Value OPening and converting over toral cycle time) 0.713*S*49=35 S 0.535*S*8.5=4.5 S Nearly 87% reduction in Start-up/Re-start Wastage - Result :: 82% reduction in Start-up cycle time.

- Benefits :: 82% reduction in Idle Time (higher machine and labour productivity) + 87% reduction in Steam Wastage (during the start Up period and also for Re-Starts during Power Failures) + Quality consistency as the Set Point is not allowed to deviate for longer time during any unscheduled stoppage.